Safety and risk management: help or hindrance to innovation?

There is a common perception in industry that safety and risk management can be a blocker to progress and innovation, or that it is a ‘tick box’ exercise to be endured rather than embraced. However, proactive implementation of safety and risk management techniques at all stages of the product lifecycle can optimise designs and minimise overall cost. So can these same techniques accelerate the market readiness of innovative technologies?

Regardless of whether innovative ideas are being introduced by startup organisations or established multinationals, return on investment

is key to the business case. Safety and risk management should always add value and offer solutions with due consideration for commercial constraints.

SAFETY THROUGH THE PRODUCT LIFECYCLE

Innovation is often most successful when an organisation’s strengths are harnessed to address current or future market needs. However, organisations may fail to consider hazard elimination or reduction through substitution of alternative lower risk solutions that could achieve the same functional needs – often at a lower cost.

Undertaking conceptual hazard identification and being open to asking ‘could this be done better?’ at the early stage of product development can eliminate hazards and wasted effort, and deliver a more profitable, saleable product.

Safety and risk management not only adds value at the concept design stage, it can do so throughout all stages of the product lifecycle. Structured hazard analysis stimulates innovation by identifying and implementing safety requirements for design, operation, training and maintenance, to enable the commercialisation of technology.

In many cases this process is required to demonstrate regulatory compliance and hurdle industry barriers to entry but, in doing so, it will help validate the completeness of product development and readiness for market.

APPLYING GOOD PRACTICE

Reducing the safety risks of an innovative system as low as is reasonably practicable is the primary goal of safety management. This can seem nebulous, but the first task is always to identify good practice, i.e. those codes and standards that are applicable. Yet when a product is novel, the obvious question becomes, ‘Is good practice available?’ The answer is almost certainly, ‘Yes… to some extent,’ and good practice from other established industries can usually be read across. Even in the developing field of autonomy for example, where gaps in good practice are known to exist, there is still a viable legal and engineering framework to build upon (e.g. Ref. 1).

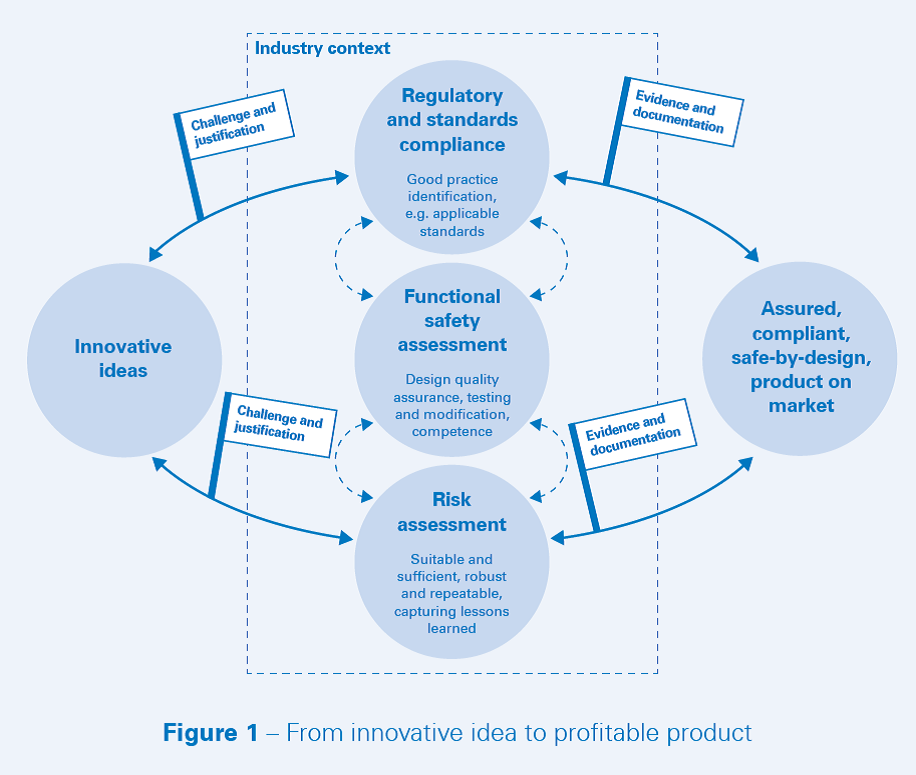

Figure 1 illustrates how innovative ideas can be driven through the complex regulatory environments of different industries all the way to assured, compliant, safe-by-design products serving their target market.

In the rail industry, the Common Safety Method for Risk Evaluation and Assessment (CSM-REA) provides a framework of three risk acceptance principles. The first is to follow relevant codes of practice. Where these are not fully applicable or developed then CSM-REA allows similar reference systems and explicit risk estimation to be considered. Guidance from Oil and Gas UK (Ref. 2) suggests engineering risk assessment when good practice is incomplete, and wider stakeholder engagement for novel approaches.

AN EXAMPLE

The Non-Intrusive Crossover System (NICS) in the rail industry, patented by NICS Ltd., allows the seamless movement of a train from a track under repair onto a second track and then back onto the first track beyond the repair site, all achieved without cutting into existing rails. This innovative solution reduces disruption and cost. Applying CSM-REA, the resulting safety case demonstrated how NICS Ltd. had identified relevant hazards and controlled associated risks by developing its design, training, installation, operational and maintenance manuals and business processes. NICS was always an innovative system capable of serving an important market need; but the body of safety assurance evidence has enabled NICS Ltd. to move beyond proof of concept to market readiness.

CONCLUSION

Even if a suitable and sufficient safety risk assessment isn’t required by law, it is still hugely beneficial. It can help to avoid potential pitfalls with innovative technologies and identify improvements. This process should be seen as an integral part of innovation, supporting the delivery of a profitable, safe-by-design new product to the market.

References:

1. Legal framework for small autonomous agricultural robots, AI & Society, April 2018.

2. Guidance on Risk Related Decision Making, Oil and Gas UK, Issue 2, July 2014.