Lessons learned from 100s of HAZOPs…or how to get the most out of the HAZOP process

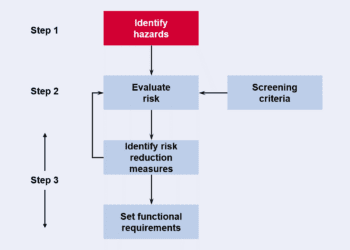

In the last issue of RISKworld we introduced some of the methods available to identify hazards associated with a process or design. One of the best known methods is the HAZOP (Hazard and Operability) study, which is an extremely useful technique for brainstorming hazards in a structured way.

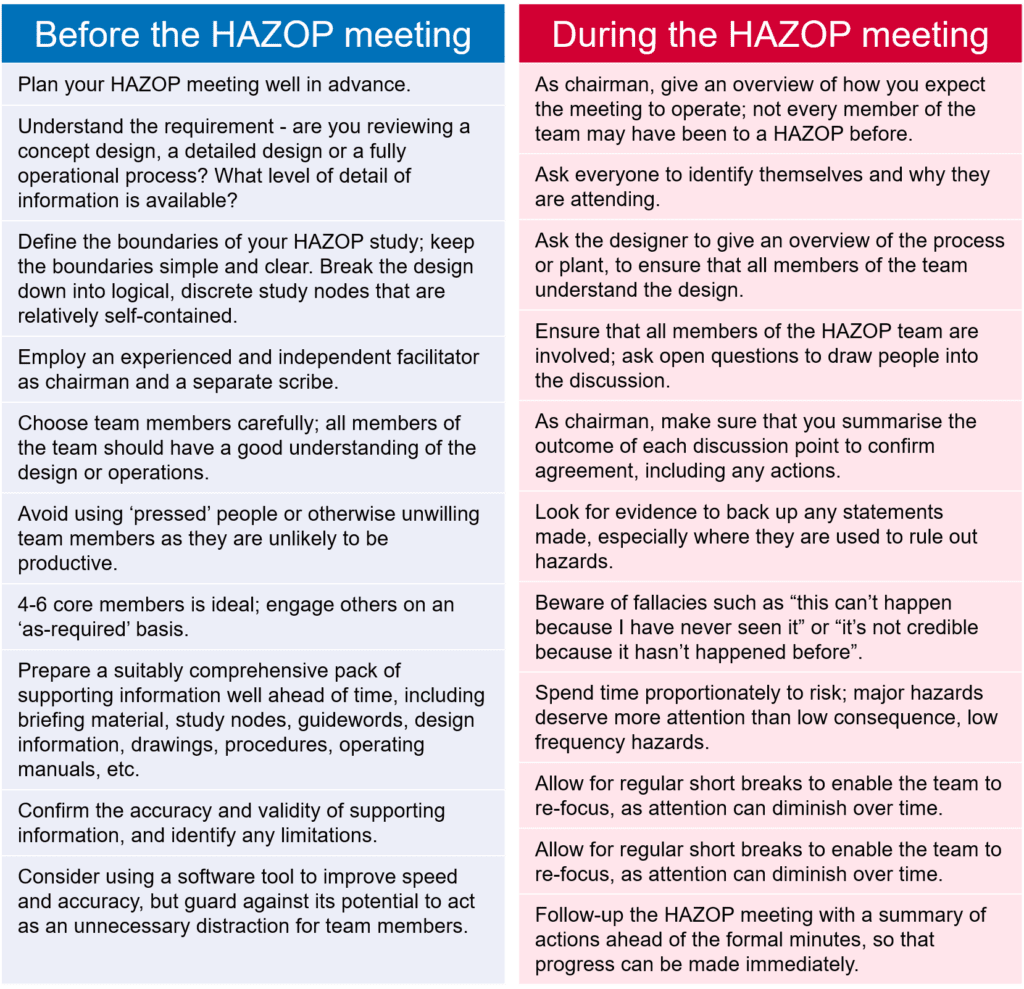

There are, however, a number of common pitfalls which can give HAZOPs an undeserving poor reputation of being unnecessarily long, tedious and unfocused. To help get the most out of HAZOPs we have pooled decades of experience collected over several hundred HAZOPs to produce a compendium of practical tips (see inset).

Investment in HAZOP planning, in terms of understanding the design, getting the right information and people together and ensuring everyone is properly briefed is a key pre-requisite to a successful HAZOP. During the study itself, the emphasis is on drawing out and focusing the collective expertise to identify and characterise the full spectrum of hazards, spending time in proportion to the real issues and associated risk.

This article first appeared in RISKworld Issue 19