Safe Ending – Managing the safety risk of nuclear decommissioning

A significant proportion of the worldwide nuclear power and fuel cycle plant have reached, or are reaching, the end of their operational life. In tackling this legacy, there is more pressure than ever on nuclear plant operators to demonstrate that decommissioning can be undertaken both safely and cost effectively.

THE PROBLEM

Globally, over 180 commercial, experimental or prototype nuclear reactors, over 500 research reactors, and several fuel cycle facilities have been retired from operation. Yet fewer than 20 reactors have been fully dismantled. Moreover, nearly 70% of reactors remaining in operation are older than 30 years and 25% are older than 40 years. Not only will the demand for decommissioning increase, but many ageing nuclear facilities were never designed or built with decommissioning in mind. As such, the associated challenges are understandably taxing.

CHALLENGES

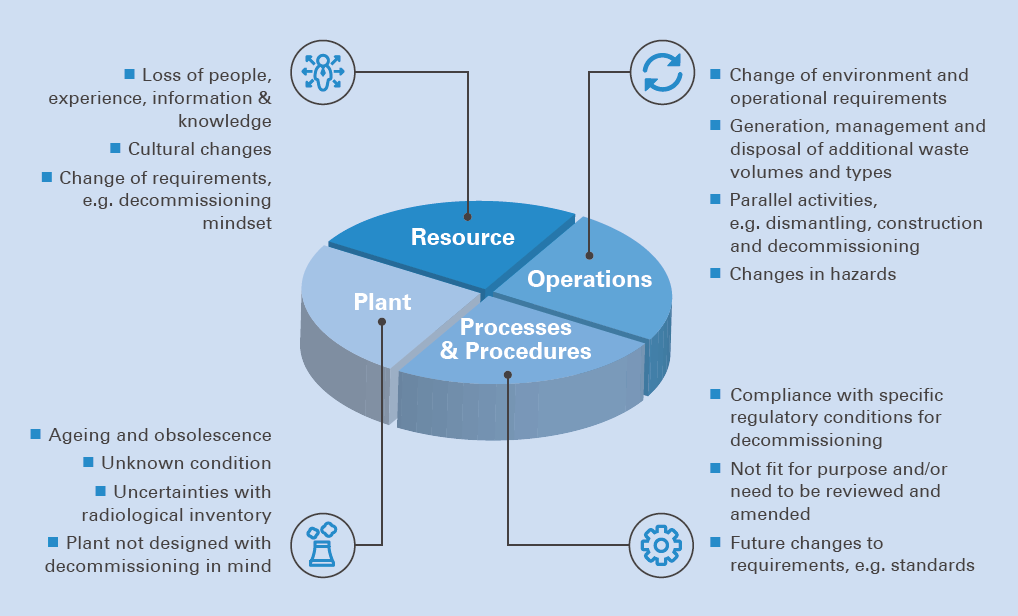

A transition from operating nuclear facilities to long-term shutdown and decommissioning represents a significant step change that brings with it a host of diverse challenges, as illustrated in Figure 1.

Figure 1 – Challenges faced by nuclear decommissioning

Resource issues can result in a loss of organisational knowledge and information about the plant’s historical operations, which can lead to large uncertainties in safety assessments. For instance, uncertainties in the radiological inventory (radionuclides, composition and form) may require worst case or overly conservative assumptions in the assessment of radiological dose to workers or the public.

Legacy plant were generally not designed with decommissioning in mind. Typical problems include restricted access, complex dismantling processes and radiological waste that is difficult to retrieve, process and package for disposal. Such issues are compounded by ageing and obsolescent systems with poor reliability, which may require repair or replacement if credit is to be taken in the safety case.

Operations during decommissioning are extensive and varied, often with many concurrent activities, such as construction, dismantling and waste disposal.

Processes and procedures are in place largely to support power operations and outages. The safety process for assessing and approving modifications is well-defined and proven. For the decommissioning phase, on the other hand, the processes and procedures may need wholesale change on a regular basis to keep pace with each transition. Likewise, the safety justification may be quite different.

SAFETY CASE CONSIDERATIONS

The early decommissioning programme (including defueling and processing of operational wastes) will continue to be carried out in accordance with the extant operational safety case. However, deeper decommissioning activities affect the character of some hazards and lead to new hazards. For example:

- Removing safety systems may erode defence-in-depth, e.g. breaking into containment, which would have otherwise been in place, to gain access for dismantling or retrieval operations.

- Introducing new activities and associated hazards, e.g. the potential for radiological exposure during manual waste retrieval and conditioning.

- Hazards arising from new plant, e.g. a new waste processing facility.

- Conventional hazards arising from dismantling, e.g. falls from height or dropped objects.

The inherent challenges involved in decommissioning can also prolong not only specific projects but entire national nuclear decommissioning programmes, resulting in further ageing of facilities, structures, systems and components, exacerbating what is already a difficult problem.

SOLUTIONS

Whilst there is no panacea, there is a range of good practices and lessons from hard-won experience that can help.

Knowledge is king

Cost-effective decommissioning starts many years before the last shutdown and involves the meticulous maintaining of historical records of inventory and plant.

Consideration should be given to using commercially available electronic systems and technology to track and manage nuclear waste systematically and comprehensively, noting that these can continue to be used throughout decommissioning.

Where information is lacking but critical to arriving at pragmatic solutions, early consideration should be given to establishing a collection programme. This might use innovative techniques such as remotely operated or autonomous robotics to sample waste, or to scan rooms and plant using 3D imaging and radiation detectors.

Decommissioning is different

Be under no illusions: The decommissioning phase of the nuclear facility lifecycle is very different to the previous operations; and requires a different mindset and different skills. Solutions that would normally be excluded from most nuclear contexts can suddenly find merit.

Retaining existing staff, whilst key for plant knowledge, carries with it an implicit (and vital) need for training for the new and dynamic environment. Bringing in experienced decommissioning engineers and project managers to help is an obvious first step, whether full-time or at key stages, or as part of a planning exercise to learn from their experiences.

Seeking advice from external specialists, including those outside the nuclear sector, may provide insight for solving specific problems, e.g. dismantling or waste treatment.

All things in proportion

It is almost certainly the case that safety assessment and engineering processes that are appropriate for new or operational plant will result in hugely expensive gold-plated solutions for decommissioning. Deterministic safety assessment criteria intended to prevent core melt are unsurprisingly onerous when applied to the comparatively low consequences associated with many of the decommissioning accident scenarios.

This and other common pitfalls are straightforward to avoid by revising safety criteria and methods for the special circumstances associated with decommissioning. More specifically, this could include:

- Screening out faults with low radiological consequences.

- Considering the use of safety measures that are lower in the risk reduction hierarchy, taking credit for the short-lived nature of the transitional risk and the ultimate reduction once decommissioning is complete.

- Defining a safety classification scheme that avoids the temptation to over-classify engineering.

- Emphasising the crucial role that optioneering plays in both arriving at a cost-effective solution and the safety justification.

- Ensuring that supporting evidence, such as design substantiation, is proportionate in robustness and extent to the associated risk.

Safety case strategy

As important as the toolkit of safety methods is, its application via a pragmatic, informed strategy is pivotal. A good strategy starts from an understanding of the key hazards and uncertainties before building the key arguments. The main departure from the classical nuclear safety case is often the scale of uncertainty, which is usually only resolved once decommissioning is underway. This requires an agility not often associated with the nuclear industry, so that the safety case, engineering solutions and processes can adapt as understanding improves throughout decommissioning. In this way, safety claims may be eased and safety measures released or downgraded, thereby saving in lifecycle costs.

CONCLUSION

Nuclear decommissioning of ageing legacy plant is a growing problem for the industry and represents a significant challenge in the years ahead in terms of assuring their safe, cost-effective and timely completion.

Good practice and lessons learnt can help meet the challenge. Early gathering of critical information, relevant training and enhancement of the decommissioning team, together with a proportionate and dynamic safety case strategy, are crucial to success.