Data Powered – Data driven risk-based planning of wind energy projects

As countries race to meet climate goals set in the 2030 Agenda for Sustainable Development by the United Nations, suppliers are pushing to deliver ever more ambitious wind energy generation projects. Effective risk-based strategies based on data-driven predictions has never been more crucial to overcoming this global challenege.

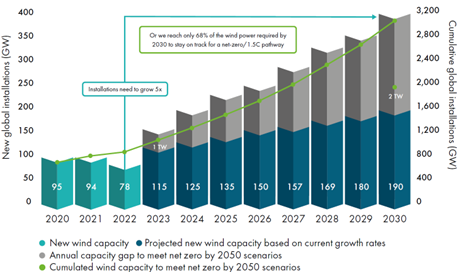

Figure 1 – GWEC Market Intelligence Projected Wind Capacity for 2030 (Ref. 1)

RISK-BASED PLANNING

Cumulatively, over 900 GW of wind power has been installed globally and the Global Wind Energy Council estimates the milestone of 2 TW in total wind power capacity will be reached before the end of 2030 (Figure 1).

Risk-based planning has become increasingly relied upon by stakeholders to anticipate, mitigate, and manage a wide range of design, operational and financial risks to ensure that projects are financially viable, and thereby help ensure that climate goals can be achieved. However, this approach is heavily reliant upon input data, and a lot of it!

The lifespan of a wind turbine is in the region of 20 to 30 years, and during that time it must be able to operate reliably and safely, even under hazardous conditions. Some of the main hazards that designers must take into consideration include:

- Turbine-related hazards, such as blade throw, overspeed leading to turbine collapse, ice shedding and fire from overheated generators.

- Other hazards, such as fall from height, drop of heavy equipment and electrocution from high voltage equipment.

However, there is a varying amount of data available to support safety management decision making – a good example is the data available for assessing and planning maintenance-related activities.

OPTIMISING MAINTENANCE

Like any other asset, wind turbines require maintenance to minimise financial losses, maximise performance, and ensure the safety of people and the environment. Crucially, though, maintenance costs can account for 10-15% of the total revenue of onshore wind farms, and 20-25% for offshore windfarms (Ref. 2).

Statistics show that while electrical system and sensor failures account for the largest proportion of repairs, the associated maintenance tends to be simple. In contrast, mechanical breakdowns tend to be less frequent, but result in the longest downtimes and usually attract much higher costs of repair.

From the safety perspective, prior to commencing maintenance activities, weather forecasting data, sensor readings and site images from drones are reviewed to determine how to address hazards safely prior to approach. The ability to interpret this data well is the key to determining the cause of any failures and making the right decisions on when and how to send out the maintenance crew.

DATA DEFICIT

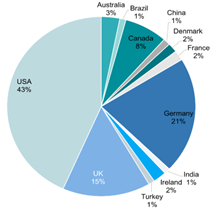

The availability of data to inform risk assessment depends on the extent to which incident data is reported and shared, as well as its quality. As depicted in Figure 2, data on turbine accidents, failures and breakdowns is mostly from the USA, UK and Germany. This does not align with installed capacity, and therefore suggests an incomplete or inconsistent availability of accident data.

Moreover, even though wind turbines have been in operation for many years, historical data is not always directly applicable. With larger and more powerful wind turbines being produced, data from turbines installed before about 2000 are not necessarily relevant, since only a few existed with a capacity above 1MW.

Figure 2 – Distribution of Wind Turbine Accidents 2010 to 2019 (Ref. 3)

There can also be uncertainties in the data quality due to:

- Limited number of site observations

- Data errors or collation issues

- Inconsistencies in hardware or software-based measuring tools

- Low temporal and spatial resolution

- Limited forecast durations

Improvements in data collection, quality and management have been achieved using Supervisory Control Data Acquisition (SCADA), Structural Health Monitoring (SHM) and Condition Monitoring System (CMS) technologies.

Each of these systems rely on sensors to provide technicians with a clear and comprehensive image of a turbine’s real-time conditions. SCADA is used to monitor and control the operational status of wind turbines, whereas SHM monitors structural components, and online/offline CMS is for monitoring of other key components (Ref. 2).

That said, the usefulness of sensory data is a function of the detection rate and the rate of false alarms. Significant improvements in sensory data quality have been found from simply optimising placement of monitoring systems, for instance.

Another challenge is the huge quantities of data generated, all of which potentially need to be stored and analysed. In practice, this means that an intelligent and automated process is required to sort, filter, analyse and store the complex information.

ARTIFICIAL INTELLIGENCE

In recent years, machine learning, a subset of AI, has gained popular attention for its ability to provide predictions based on complex multi-dimensional data. In this case, the idea is that machine learning uses operational data to train a black-box model to provide early advice for predictive maintenance.

Although progress has been made on this front, there’s still some way to go to deal with data uncertainty and missing data; and methods are needed for proving stability and robustness of predictions. This is especially true when using historical data to train the model, as there can be a lack of required detail as a result of data collection or storage methods. With respect to failure data, there may not necessarily be sufficient information on the causes of failure.

To some extent the methods employed in big data analysis can help with some of these issues – for example, post-processing can reduce the data storage requirements and help accommodate patchy data.

CONCLUSION

Using tools and techniques that are rapidly evolving, big data collection and analysis for operational wind turbines has the power to transform the industry. By integrating operational data into strategic risk-based planning processes, wind energy project stakeholders can make informed decisions, optimise resource allocation, ensure safety, and maximise the long-term value and sustainability of wind energy investments.

References

- Global Wind Energy Council, 2023. Global Wind Report 2023. Brussels, Belgium. https://gwec.net/globalwindreport2023/#:~:text=KEY%20HIGHLIGHTS&text=2023%20should%20be%20the%20very,GW%20per%20year%20to%202027.

- Chen, H., Chen, J., Dai, J., Tao, H. and Wang, X., 2022. Early fault warning method of wind turbine main transmission system based on SCADA and CMS data. Machines, 10(11), p.1018.

- Ertek, G. and Kailas, L., 2021. Analyzing a decade of wind turbine accident news with topic modeling. Sustainability, 13(22), p.12757.