Breaking it Down – A brief guide to creating effective operating procedures

Ensuring that all operating and maintenance procedures are easy to follow, accurate and up to date can be a challenge, but it is essential for accomplishing safety critical tasks and meeting corporate and regulatory expectations. To meet this challenge, human factors best practice can be boiled down to help improve the usability of procedures, resulting in fewer human errors and violations, and greater compliance.

© Shutterstock

COMMON PROBLEMS WITH PROCEDURES

Although operating and maintenance procedures may be developed by operators with extensive experience, the way in which procedures are written may not always make them easy to follow without error, particularly in the case of new operators. A common failing is that as things change (e.g. new equipment is introduced, roles and responsibilities are re-assigned, etc.), the procedure isn’t updated. In contrast, sometimes procedures may be modified piecemeal over time by various individuals until they no longer accurately reflect the tasks in question. Other commonly observed issues include:

- Procedural steps are written as lengthy paragraphs, containing a mixture of instruction and information

- Safety critical tasks are not clearly identified

- The operator responsible for carrying out each step is not clear

- Poor document control

Poorly written procedures increase the potential for operators to make errors. Even worse, if a procedure is out of date and cannot be correctly followed then shortcuts may be taken.

ESTABLISHING AN EFFECTIVE PROCESS

It is important that there is a robust corporate procedure that lays out the process to be followed for the development and ongoing control of operating procedures and work instructions.

Key considerations include:

- Assigning responsibilities for procedure development and management

- Establishing a robust process for determining whether the procedure is safety critical or not

- Setting and enforcing requirements for procedure checking, approval and periodic review

DESIGNING FOR USABILITY

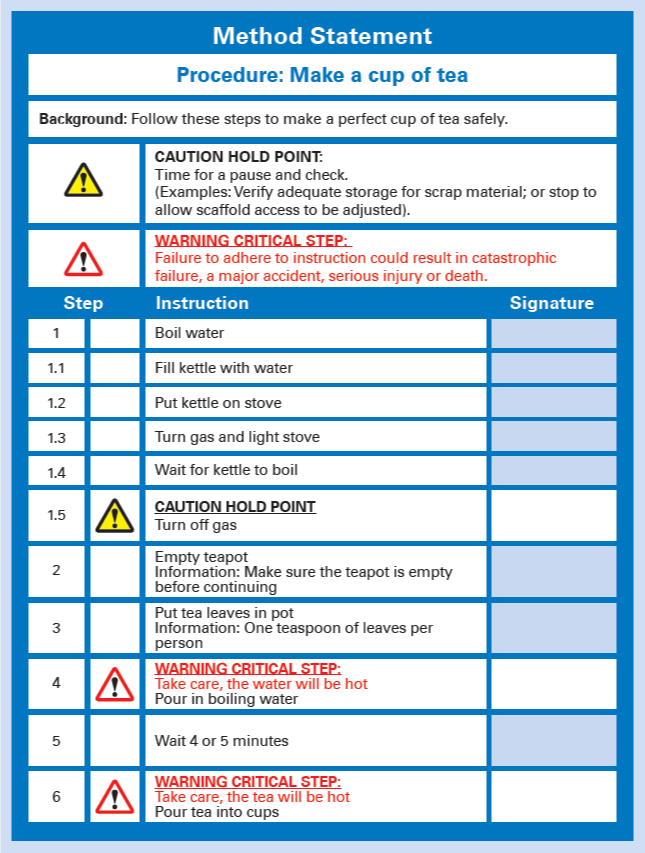

When deciding procedure structure and content, established human factors guidance on usability should be applied. Taking account of best practice will reduce the potential for human errors and procedural violations and encourage compliant use. Some examples of key points are:

- State the criticality level of the activities covered by the procedure, and summarise any key risks at the front of the document

- List any equipment or Personal Protective Equipment (PPE) that is required

- Limit each step to a single operator action

- Use short, simple sentences, in the present tense

- Number all steps and make appropriate use of check boxes to help operators keep track of their place in the task sequence

- Clearly differentiate between task instructions, warnings, cautions and additional information

- Consider additional sign-offs for safety critical tasks

Once a procedure has been drafted, it is important to pilot it with operators who will be using it. Indeed, a key requirement for the production of effective procedures is to ensure the involvement of all end-users throughout the process.

THE BENEFITS OF HIERARCHICAL TASK ANALYSIS

Another crucial requirement is that the procedure’s steps must accurately reflect the task as performed in practice.

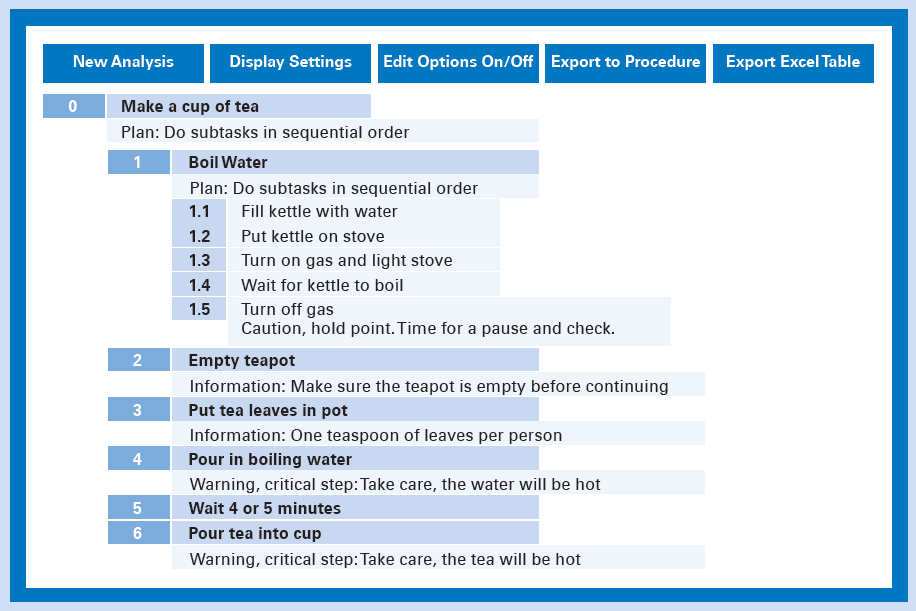

Hierarchical Task Analysis (HTA) is a proven method for capturing and describing a task or activity down to a detailed level. Typically, HTA is based on task observation or a talk-through with the operator, and involves systematically identifying and sequencing task steps to enable the accurate update of an existing procedure or development of a new one.

Software may be used by nonspecialists to support this, enabling complex activities to be broken down into their constituent steps (see Figure 1). Safety critical steps can be identified and warnings or cautions assigned. Task steps can then be transposed electronically into procedure format (Figure 2). Once agreed, the new or revised procedure provides the ideal starting point for Safety Critical Task Analysis (SCTA) or Human Error Assessment (HEA).

Figure 1 – Example Hierarchical Task Analysis

Using such a tool has a number of benefits, including:

- Helping operators gain a clear understanding of task steps and sequencing, encouraging ‘buy in’ to the development process

- Facilitating the involvement of operators in developing accurate, user-friendly procedures, quickly and efficiently, providing the starting point from which further refinement can take place

- Standardising the procedure development process, structure and format

- Enabling details of tasks, sequencing and supporting information to be easily modified

CONCLUSION

Ensuring that procedures are easy to follow, accurate and up to date is essential for safe working and more generally minimising the potential for error or non-compliance.

Applying human factors knowledge, including the use of HTA and associated tools, can help ensure that procedures are optimised and effective, and that corporate and regulatory expectations are met.