Introduction to RAM modelling

Reliability, Availability and Maintainability (RAM) are system design attributes that can have a substantial impact on the lifecycle cost and performance of an engineered system. In RAM modelling, Reliability is the probability of zero failures over a defined time interval. Availability is the percentage of time a system is considered ready to use when tasked. Maintainability is a measure of the ease with which a system can be restored to operational status following a failure.

Whilst the word reliability can be traced back as early as 1816 to poet Samuel Coleridge, it was not until 1941 that German aircraft designer Robert Lusser recognised the need for a separate reliability engineering discipline. It has since become commonplace throughout all engineering-based industries, including oil and gas, nuclear, manufacturing, defence and transport.

WHY CONDUCT RAM STUDIES?

The aim of a RAM study is to identify any significant causes of loss of operational availability or issues that may limit the production throughput and then propose improvements to the design or maintenance regime that enable RAM targets to be met.

Ideally, a RAM study (supported by a Failure Mode, Effects and Criticality Analysis, FMECA), would be conducted in the early stages of a project. This can then be reviewed and updated as the project progresses, with minimal disruption and cost to a project.

HOW ARE RAM STUDIES CONDUCTED?

Normally a “bottom-up” approach to RAM modelling is taken. This starts with the system components and examines the design to determine the effects of individual component failure, often using a Reliability Block Diagram (RBD). The components making up the RBD are linked using reliability logic rather than their physical relationship.

Equipment failure data are applied to each component in the system. These data can be obtained from several sources such as manufacturing data, design specifications or operational experience. The key to a successful and accurate study is the quality of the failure data. In cases where failure data specific to the actual component are not available, generic, industry standard sources are normally used, e.g. OREDA 2009.

Using specialised RAM software, operational availability can be predicted and analysed. The software may be industry standard packages such as MAROS or Reliability/Availability Workbench, or in-house developed spreadsheets. The main advantage of the software is that it enables the rapid evaluation of design options and the sensitivity of the results to changes in the underlying data. Quantitative results provide not only headline RAM figures, but also allow the identification of critical components.

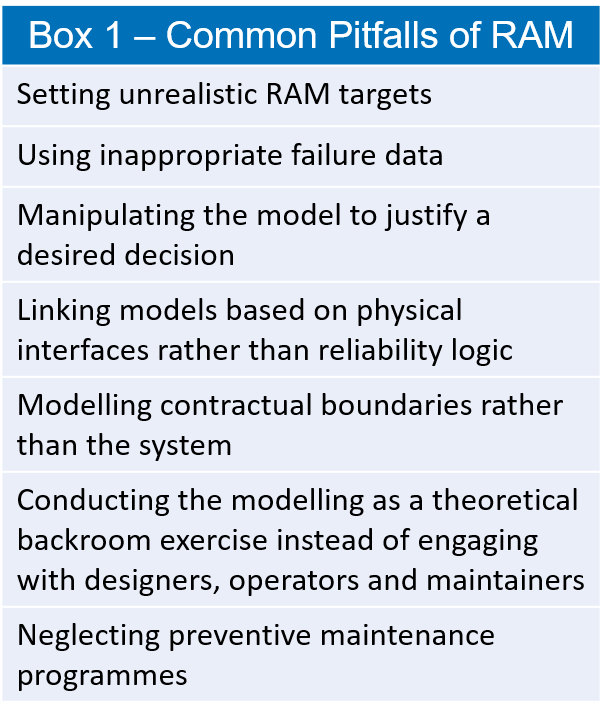

Some of the more common pitfalls to avoid when conducting RAM modelling are highlighted in Box 1.

KEY QUESTIONS

Once the baseline RAM of the system is established, the following considerations should be addressed:

- Has the design met all the RAM requirements and targets?

- Can the design or operation be modified to increase the availability of the system?

- Can the maintenance strategy be revised to reduce downtime in the event of failure?

For availability-critical equipment, a targeted preventive maintenance programme should also be instigated, which may include monitoring to detect changes in performance or deviations from normal operating ranges.

BENEFITS

RAM modelling identifies areas of vulnerability which can affect operational availability and quantifies which assets and associated maintenance activities dominate downtime. Knowing this, the system design can be optimised, including its configuration, level of redundancy, component selection and supporting maintenance strategy. As well as suggesting tangible improvements, a RAM programme can provide confidence that the system will meet its operational targets and support wider project decision-making.

CONCLUSION

RAM modelling has a long history in engineering sectors. Used appropriately, RAM modelling is an effective tool for assessing system reliability, availability and maintainability, and is crucial to support the through-life viability of a project

This article first appeared in RISKworld issue 28