The effects of ageing and the implications for risk and safety management

One of the knock-on effects of the rising energy demand is a push to extend the life of already ageing installations across the major hazard industries, notably in the oil, gas & chemical and nuclear power sectors. For example, as operations in the North Sea approach their 40th anniversary, many platforms are approaching or have exceeded their design life. Similarly, the UK’s existing fleet of ageing nuclear reactors is being asked to fill the energy gap as the long wait for new build nuclear energy continues. Indeed, more and more facilities throughout the world are likely to exceed their original design life, often by many years.

THE AGEING PROCESS

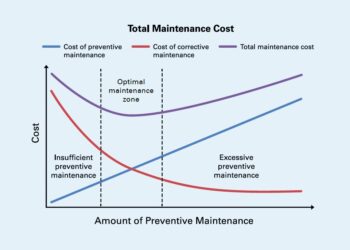

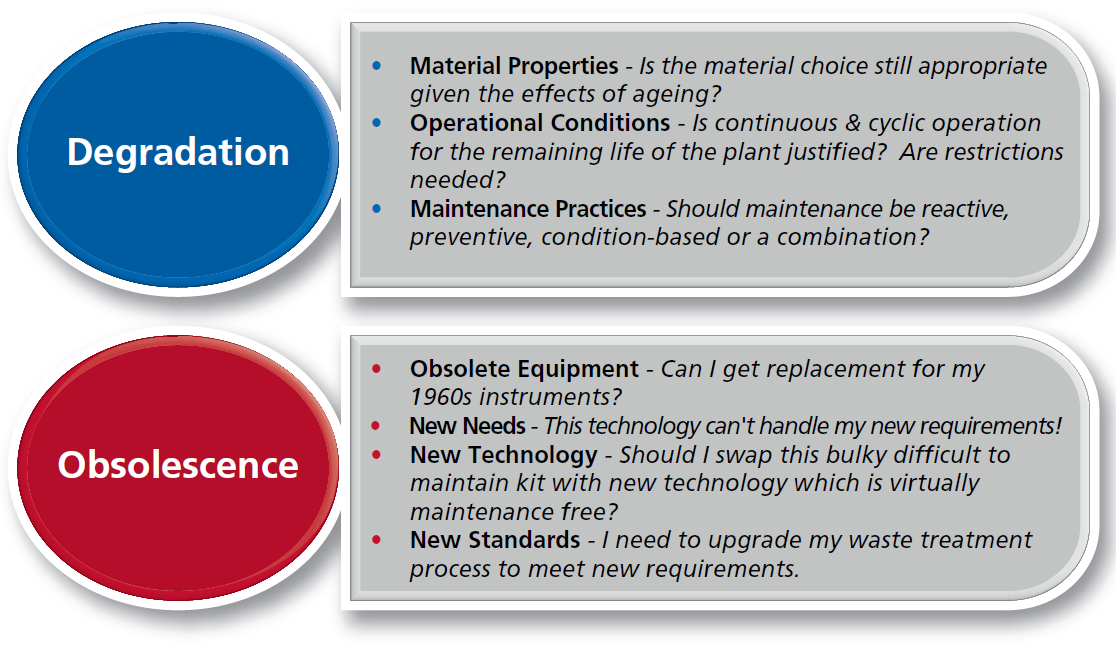

The ageing phenomenon is not necessarily related to the chronological age of equipment, but is a function of its condition and how this is changing. Equipment which faces harsh environmental, chemical or operational conditions, is subjected to poor maintenance, orhas a high cycle rate is more likely to deteriorate over time. Thorough monitoring of plant condition and tuning of maintenance and upkeep requirements is a logical step towards sustaining or improving overall reliability and maintainability.

CONDITION NOT TIME

Condition-based maintenance programmes aim to improve knowledge of equipment condition, thus allowing maintenance to focus on areas of immediate concern. This is a marked change from the conventional time-based approach where maintenance scheduling is ‘set in stone’ regardless of physical condition or performance. With a condition-based scheme, operators learn to ‘Look, listen and feel’ and are able to flag-up issues before failures occur.

GOING, GOING, GONE!

Another symptom of ageing facilities is the increasing likelihood of being unable to replace equipment on a like-for-like basis as components become obsolete. This is potentially problematic for items requiring periodic replacement and can be a major issue for systems reaching the end of their serviceable life. In identifying suitable replacements, it is crucial to establish the fundamental function required, especially those that are safety related. Moreover, there may be an opportunity to improve safety and operational availability by reviewing a number of alternative options. One particular issue is that a new equipment option may be software controlled, which can increase flexibility, but at the expense of safety justification, which is less straightforward.

AGEING RISK MANAGEMENT

The ageing process can significantly alter the performance, availability and risk profile of a facility. The integrity management of ageing installations depends crucially on knowing equipment condition and associated degradation processes, as well as identifying obsolescent systems or components. As a result, age-related issues are playing a much greater part in thorough reviews and periodic reviews of safety. Regulators such as the UK’s Health and Safety Executive (HSE) and the Nuclear Installations Inspectorate, and Norway’s Petroleum Safety Authority are also stepping up their scrutiny. Last year, for example, the HSE launched an Ageing and Life Extension Inspection Programme, which aims to ensure that risks to asset integrity associated with ageing and life extension are controlled effectively. The first duty holder inspection has now been completed and follow up inspections are set to continue.

CONCLUSION

As the demand for energy continues its inexorable rise, the effects of ageing on safety and availability of major hazard facilities are likely to present new challenges to operators across the globe.

This article first appeared in RISKworld Issue 19