Asset integrity management

Asset Integrity Management (AIM) offers asset owners and operators the ability to manage risk and assure the integrity of assets throughout their lifecycle. The purpose of AIM is for an organisation to be able to say with confidence, based on the evidence that “our assets are safe, reliable and efficient, and we know it.”

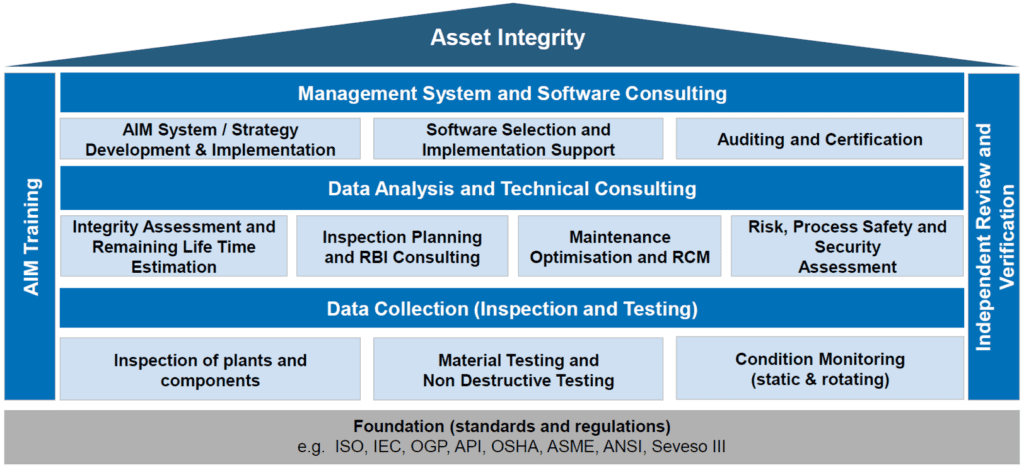

TÜV Rheinland Risktec provides a broad range of services to support effective AIM across all floors of the ‘AIM House’:

Management system and software consulting:

- Developing AIM systems in compliance with ISO 55000 series

- Developing process safety management systems

- Developing equipment reliability processes

- AIM software selection and implementation support

- Performance monitoring, auditing and management review

Data analysis and technical consulting:

- Integrity assessment including fitness for service, corrosion control, failure analysis and lifetime extension

- Risk and reliability management including risk-based inspection (RBI), reliability-centred maintenance (RCM), reliability, availability and maintainability (RAM) modelling and safety integrity level (SIL) assessment

- Process hazard analysis (PHA) including HAZOP study, LOPA, FMEA and physical effects modelling

- Security vulnerability analysis

- Safety case analysis including safety-critical element (SCE) management, quantitative risk assessment (QRA) and ALARP assessment

- Data analysis of maintenance, inspection and testing results to optimise performance

- Incident investigation and root cause analysis

Data collection (testing and inspection):

- Inspection of industrial plants and components, covering all stages of QA/QC monitoring from manufacturing (vendor inspections), construction/installation (on-site and commissioning inspections) and operation (in-service inspections)

- Non-destructive testing (NDT) using conventional, advanced and special technologies, and robotics/remote-control machines

- Material testing and analysis

- Non-destructive diagnostics and condition monitoring for static and rotating equipment

We also provide various training courses to help improve competency in AIM, as well independent verification of the implementation of all elements of the AIM system.

“Our approach to AIM helps to bring together under one roof the activities and disciplines that so often suffer from a ‘silo mentality’ within an organisation.”