Improving efficiency in safety in a cost-conscious world

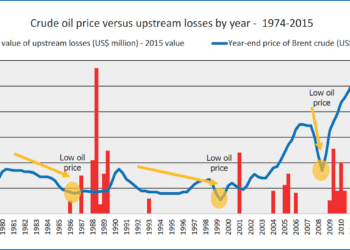

Every industry cycles through periods of favourable and unfavourable economic conditions. The petroleum industry, for example, having enjoyed several years of high oil prices, is today reeling from the impact of prices not seen for six years and at levels that are lower than the breakeven cost of many ventures. The inevitable response is to cut operating costs and delay investment in new projects, which all makes for gloomy headlines and the harsh reality of people losing their jobs. But with the gloom comes the opportunity to improve the efficiency of operations, something that is rarely a top priority when budgets are plentiful and there is huge programme pressure.

This article highlights some examples where more innovative approaches to safety and risk management can contribute to improving efficiency and performance.

MAXIMISING RECYCLING

Whilst it is true that no two technical safety studies are ever precisely the same, there are often many similarities. Significant time can be saved by basing a new study on the most recent and relevant good practice elsewhere rather than attempting to reinvent the wheel. Moreover, putting in a little effort upfront to standardise approaches can save considerable effort in the long run, for instance by using proven templates for hazard registers, bowtie models and HAZOP reports, as well as adopting streamlined QRA methods and standardised models.

ENABLE WITH SOFTWARE

Use of technical software is common in safety risk analysis to solve complex numerical problems in an efficient way. But many of the well-established products do not link well with each other. For example, CFD explosion analysis software does not automatically produce results in a form that can be used by QRA software. Developing in-house tools to pre- and post-process data such that it can be readily used between different software not only saves costs by improving efficiency, but also improves the quality of the results and value of the findings.

CHALLENGING NICE-TO-HAVES

When more and more preferential requirements are added into standards by well-intentioned technical authorities, the standards can lead to gold-plated engineered solutions. In fact, the safety risk may even be higher than a simpler, cheaper solution based on inherent safety thinking. A robust ALARP (As Low As Reasonably Practicable) process enables a transparent challenge to nice-to-have requirements so that the design focuses on what is necessary rather than what is preferential. What is essential here is highly experienced expert judgement during option studies and ALARP assessment, which focuses on delivering a proportionate risk-based design.

TAP INTO GRADUATE POTENTIAL

Many companies underestimate the capabilities of graduates and assume that, until they have completed the traditional two year graduate training scheme, they are a burden on the organisation. But given the right opportunity and support, graduates can be a very cost-effective resource. One example is to ring fence two or three graduates to work at a facility to concentrate on improvements in equipment reliability and maintenance. Experience has shown that their cost will be repaid many times over due to reducing equipment maintenance backlog by eliminating unnecessary work, introducing more advanced inspection techniques and increasing equipment reliability.

LEARN BY DISTANCE

Training budgets are amongst the first to be scrutinised during hard times. However, technical training is rarely optimised and often simply involves a selection of courses to travel to and sit in a classroom. E-learning has some clear cost saving advantages in that people can learn from wherever they have internet access and at times that best suit them. Furthermore, e-learning allows measuring of progress using standardised tests which can be difficult to achieve by an instructor alone. Not everything can be taught using e-learning, such as HAZOP facilitation skills, which require live interaction with other people, but most technical safety skills lend themselves very well to online learning.

PACKAGE CONSULTANCY SUPPORT

During the busy times it is common for projects to ramp up resource with large numbers of individual contractors. This is generally easy to organise and secures resources quickly. However, this approach has considerable hidden costs: the capability is limited to the skills of the individuals and if delays occur the costs are still incurred. Furthermore, when the end of the project is in sight the resource moves on and knowledge is no longer available. A more cost-effective and delivery focused approach is packaged consultancy support. Here, a scope of work is clearly defined with specific deliverables and prices. The consultancy draws upon its people with the required skills and largely conducts the work from its own premises with close contact with the client throughout. The client is always in control, the consultancy only works when the client has a need, and cost savings are realised.

CONCLUSION

Unfavourable economic conditions necessitate that organisations cut costs and delay investment. This provides safety professionals the opportunity to improve efficiency and performance of operations (whilst maintaining standards), something that is not always so easy when the industry is booming.

This article first appeared in RISKworld issue 28