Accidents waiting to happen…

Why do things go wrong? A relatively simple question, but one that is fundamental to the risk management of any organisation. Whether it is the computer failure that delays the payroll, prescribing the wrong medication, an object falling from height or a fire in a warehouse, the chances are that at some point there was a human involvement that could have been better managed. Unfortunately we never have the required hindsight in advance. But if we can understand the underlying factors that influenced the action, then we will be in a much better position to improve performance for the future.

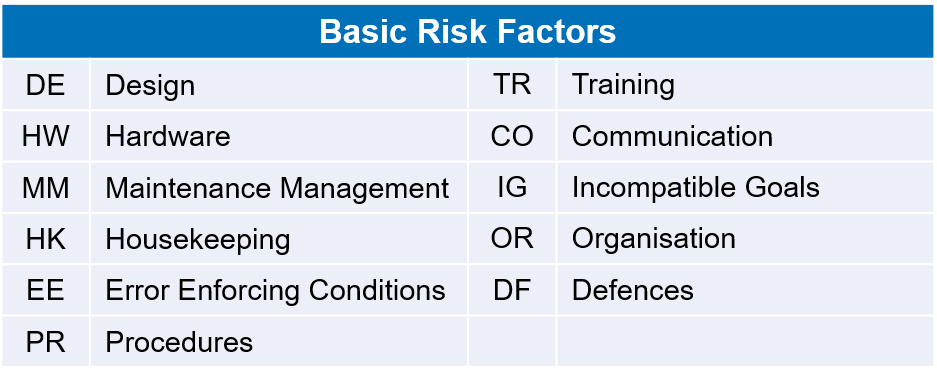

In 1986 the Universities of Leiden and Manchester were asked to consider this question. They identified that 75% of incidents are the result of organisational failures, leading to the conclusion that to prevent incidents, control of the working environment is the most effective approach. Their research identified 11 basic risk factors (Box 1) that influence the work environment and have a direct bearing not only on those incidents which have happened but also those which have yet to occur.

Box 1

THE TRIPOD THEORY

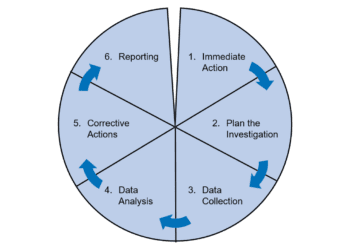

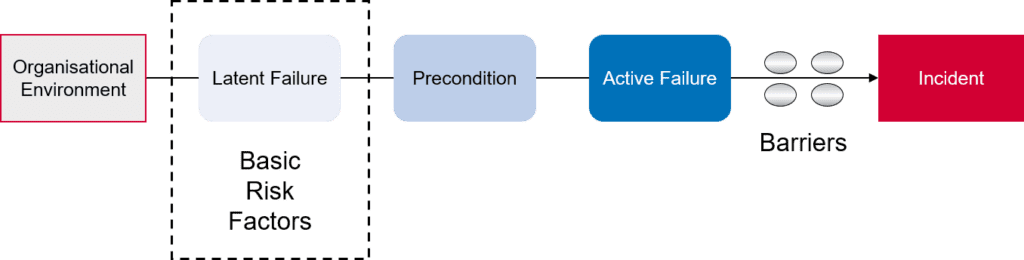

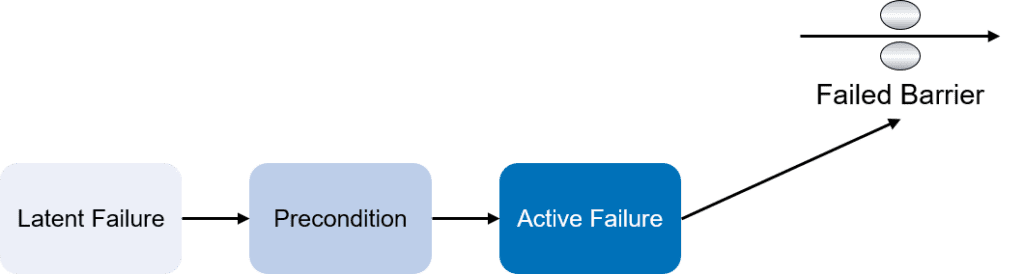

To assess an incident requires understanding not only what happened, but also why it happened. Any incident occurs because protective barriers fail. These barriers can fail when people make mistakes (the ‘active failure’), which are more likely with a ‘precondition’ that was encouraged by a ‘latent failure’, which was established by the ‘organisational environment’ (the basic risk factors). This is the model of the Tripod theory (fig. 1).

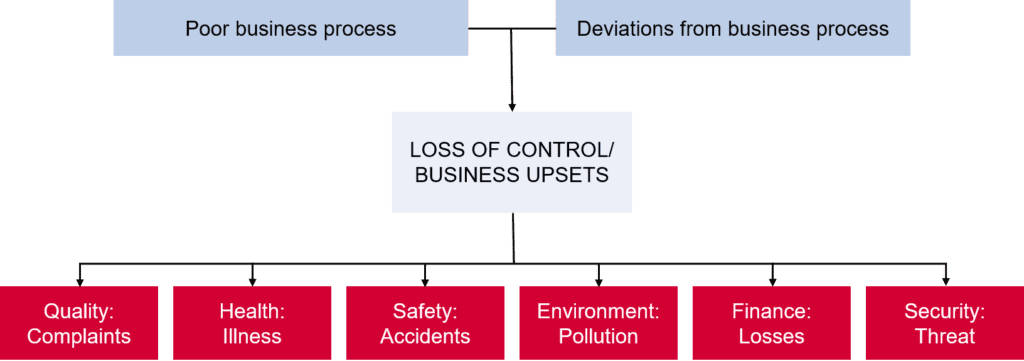

Although we tend to think of incidents purely as injuries to people, incidents occur in many forms and affect many parts of any business. Each incident, whether of a financial, security, safety or environmental nature, has its roots in the basic risk factors. Only the consequences of bad risk management are different (fig. 2).

Figure 1

Figure 2

THE TRIPOD CAUSE-CONSEQUENCE DIAGRAM

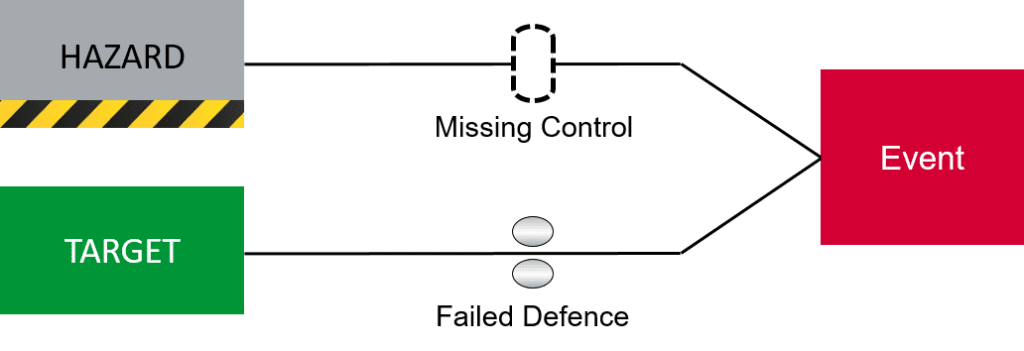

Any incident may be represented as:

Figure 3

Where the hazard (the potential to cause harm) is allowed to come into contact with the target (e.g. a person, an asset, a process) there is an incident. Normally the target is protected and the hazard contained by protective barriers – the failure of one or more of which allows the incident to occur (fig. 4).

Figure 4

As well as correcting the active failure, the accident investigation needs to track back from the missing or failed barriers to identify the underlying causes. Replacing the barrier allows resumption of the operation, but identifying the basic risk factors allows correction of the underlying causes, so preventing the active failure from recurring (fig. 5).

Figure 5

Additionally, because the basic risk factors are representative of the work environment, any improvements made to one risk factor should also spread throughout the organisation and prevent further incidents elsewhere.

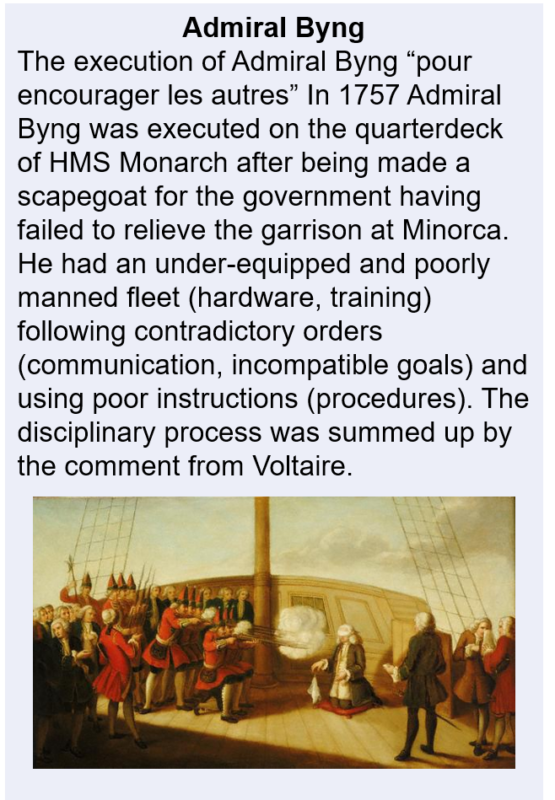

Fortunately organisations are moving away from investigations to ‘kick butts and take names’ and the incidence of the person involved being made an example of (sacking, disciplinary actions) ‘pour encourager les autres’ (Box 2) is decreasing. Incidents should be investigated to identify causes to prevent reoccurrences, not to apportion blame.

Box 2 – The execution of Admiral Byng “pour encourager les autres”

THE TRIPOD TOOLS

In the same way that incidents are investigated to identify common organisational failures, it is also possible to conduct a forward looking audit, against the same basic risk factors, to identify weaknesses in areas of an organisation.

These Tripod methods are captured in two tools which are used by Risktec to help organisations make sustainable improvements in their risk management:

- Tripod Beta; an incident investigation tool – the reactive approach

- Tripod Delta; an organisational performance audit – the proactive approach

CONCLUSION

With well over 10 years of research and science built-in, the Tripod tools provide a solid foundation for making sustainable improvements and preventing those accidents that are just waiting to happen.

This article first appeared in RISKworld Issue 5.