Integrated use of CFD in QRA

CFD FOR DESIGN

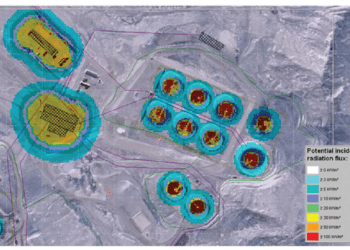

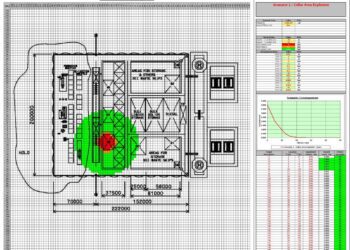

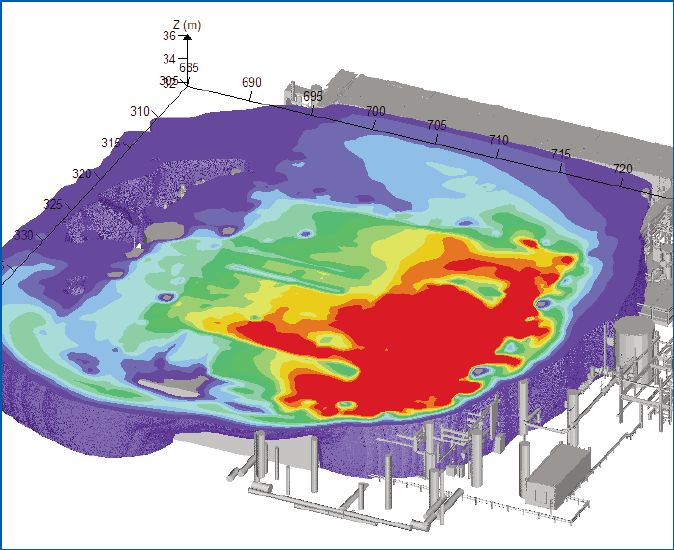

Computational Fluid Dynamics (CFD) studies are often performed to assess the dispersion of flammable or toxic releases, or overpressures resulting from explosions. Traditionally, the output of such studies is a report containing 2D and 3D graphical presentations of results, sometimes accompanied by short videos showing how the dispersion or overpressures develop over time. The results may also be combined with event frequencies to derive ‘exceedence plots’ which indicate the likelihood of overpressures exceeding certain magnitudes.

These studies are generally targeted at designers with a view to improving understanding and informing the design, e.g. for developing a blast wall design to protect against a 1 in 1,000 year explosion.

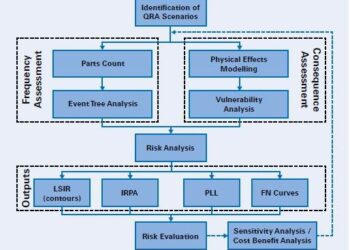

Quantitative Risk Assessment (QRA) is often used to assess probabilistically the risks associated with a facility, including those due to explosions.

In principle, CFD should enable more refined QRA modelling of explosions, but often the CFD output is of limited benefit due to a range of factors, including, for example:

- The large number of scenarios that need to be considered in the QRA, compared to the limited number of design cases.

- Extracting information from a CFD report can often be difficult and time consuming, and relies on manual estimates from figures or interpolation from data tables.

Ironically, this means that non-CFD consequence modelling software may have to be used instead, noting that this approach is unable to take specific account of the facility geometry.

In summary, the traditional CFD approach produces a fairly standard set of outputs which is not suited to the development needs of QRA models.

CFD FOR DESIGN & QRA

Better integration of CFD studies and QRA can be achieved by specifying the outputs required by the QRA in advance and having raw data from CFD simulations delivered in electronic formats that can be interrogated easily. In the past, this has been hampered by the significant volume of data involved, but modern data storage and transfer arrangements mean this is no longer such an issue. With the whole dataset available, the inherent limitations of the data published in the CFD report no longer applies.

Making it clear from the start what results are needed for QRA can also reduce the requirement for additional analysis runs. For example, by specifying a grid of overpressure results across the facility rather than just at specific design elements means that it can also be used by the QRA to answer much wider questions relating to the effect of overpressures at different locations (an issue that would traditionally involve time consuming iterations with the CFD analyst).

Recent experience tells us that it is possible to obtain targeted outputs of raw data from CFD studies without significantly affecting cost, provided they are specified in advance.

OPTIMISING QRA

Making the most of CFD data depends on building the QRA model so that CFD output can be imported directly, without the need for post-processing. Achieving this relies on a consistent specification and format between the QRA and CFD. On occasion it is also possible to automate this data transfer process. Overall, this makes things much more efficient and enables more straightforward updates to the QRA following revisions to the CFD.

Ultimately, this should result in a QRA that is informed more explicitly by CFD results, enabling a more representative evaluation and understanding of risk, and its sensitivity to potential explosions.

CONCLUSION

As the use of CFD to support QRA continues to increase, getting the interface right at an early stage can reap real benefits in cost-effectiveness, as well as producing a better understanding of risk and, by extension, more focused risk mitigation.

This article first appeared in RISKworld Issue 20