Safety Cases for the offshore wind industry

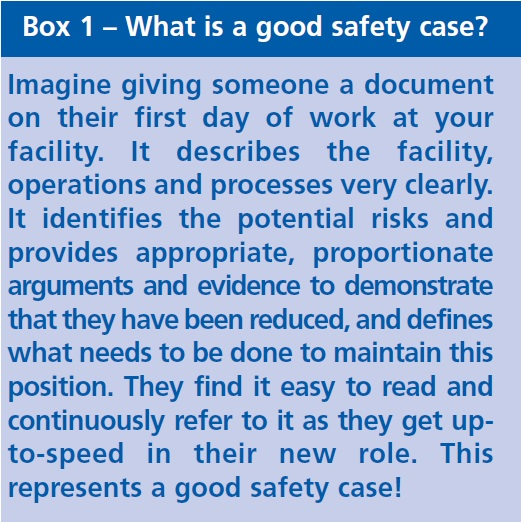

Safety cases well and truly divide opinion. Their critics see an isolated exercise of complex analysis and written work that does not reflect the real world and sits on a shelf gathering dust. Whilst regrettably there is historical evidence to justify these views, a good safety case is an excellent way of ensuring projects are conceived and executed safely (see Box 1).

But is the safety case approach relevant and appropriate for the wind industry? For the majority of onshore wind farms in remote, rural locations, the answer is most likely to be ‘no’. The potential risk to people and assets can be readily discounted through observation and judgment without the need for a formal safety case. For offshore wind farms the situation is quite different. Managing offshore assets, and in particular getting people on and off safely, presents a number of significant challenges and risks.

All about the journey

Whilst a safety case is the written demonstration of why a plant or facility is safe, it should not be seen as a retrospective justification or a piece of creative writing to ‘get away with’ an inadequate solution. A truly safe outcome can only be achieved by fully integrating design and safety assurance activities to build and develop the safety case as the project progresses.

Understand the scope

From the outset, you should be clear on what plant and operations the safety case covers. For example, it might not have to include the onshore substation or access vessels if these are operated by others. That said, it would need to dove-tail seamlessly with any interfacing safety justification.

Involve key stakeholders

You should involve key stakeholders to ensure that interfaces are managed proactively. Moreover, involving people with hands-on experience of the design and operation of a wind farm is critical. They know what goes on in the real world!

Don’t re-invent the wheel

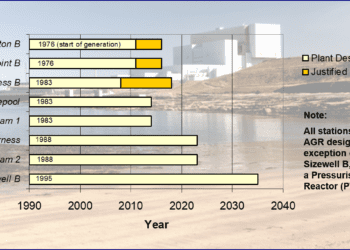

Safety cases have been around a long time in other industries, particularly nuclear power and oil & gas. A huge amount of time and effort has gone into developing best practice, which can be cherry-picked for an offshore wind farm safety case. This applies equally to the overall approach as well as the tools and techniques.

Proportionality is key

The level of safety case detail, and the depth of supporting analysis should be proportionate to the associated risk. Too little and your safety case may be weak or inadequate. Too much and you’ll waste valuable time, effort and resources. Safety cases may be large and complex for a nuclear installation or very brief and simple for less hazardous facilities such as wind farms.

Safety case vs OHSMS?

A safety case doesn’t need to go back to first principles to demonstrate safety. A corporate or wind farm specific Occupational Health and Safety Management System (OHSMS) should provide the framework for safe operations, which can be enhanced by the output from the safety case.

Life-cycle safety case

A safety case is a living, evolving entity. As such, it is important to identify key milestones at the outset relating to the demonstration of wind farm safety at each stage, including design, construction, commissioning, operation and decommissioning. Can some of these milestones be combined? What safety case structure is appropriate for each milestone?

Future proofing

No matter how well written a safety case is, risk reduction is only achieved by implementing the safety case. Equally, as things change, such as operations, equipment and the organisation, so the safety case should evolve to capture the real world and trap any new hazards. This takes dedication and effort.

My mate, safety case

Although there isn’t a one-size fits all solution because of the diversity of the wind industry, if you follow the principles outlined above you should end up with a valuable and proportionate safety case process … that doesn’t leave a bitter taste in your mouth.

This article first appeared in RISKworld Issue 24