Periodic review – opportunity or chore?

Good practice calls for a periodic review of major hazard safety cases to ensure that the ‘case for safety’ remains valid. Indeed, many regulatory regimes and corporate standards have a requirement for ‘periodic’ or ‘thorough’ review, and provide guidance on the frequency and content of the review. At first sight, the potentially wide ranging nature of periodic reviews can appear daunting and onerous, with the potential to place a heavy burden on resources. But a well managed periodic review provides a great opportunity to strengthen the connection between the safety case and the real world.

REVIEW SCOPE

In undertaking a periodic review, it is important to go beyond a desktop study of the safety case documentation and recognise that the case for safety is based on real plant, processes and, arguably most importantly, people.

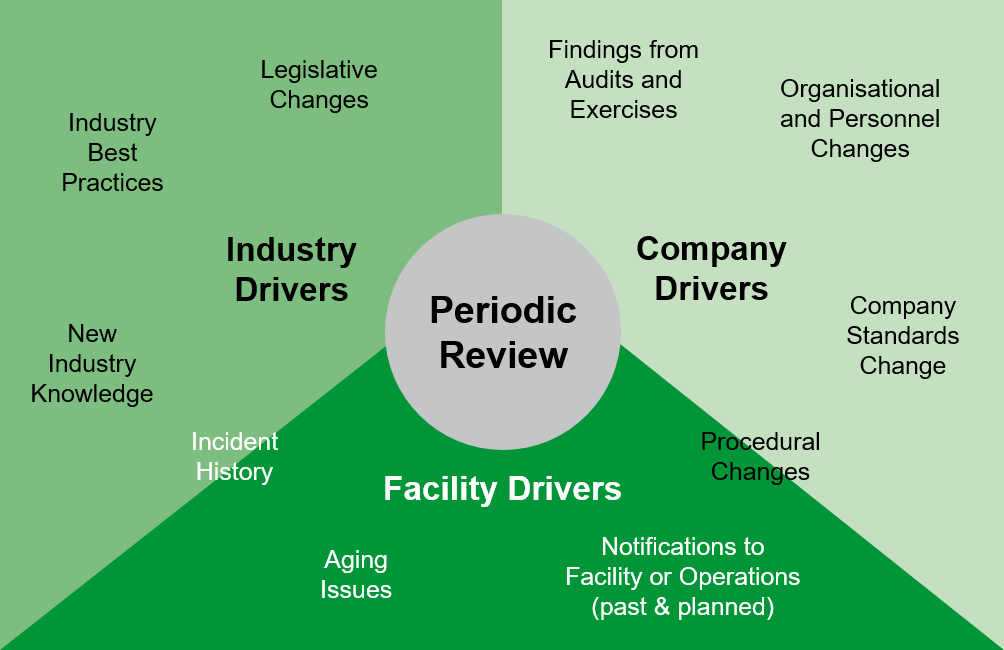

Typically, the review will need to focus on changes to standards, plant, operations and organisation, as illustrated in Figure 1.

Figure 1 – Periodic Review Topics

It is important to recognise that periodic review is not intended to be a rewrite of the safety case or a comprehensive update of the safety management system, although its conclusions may affect both.

PRACTICAL IMPLEMENTATION

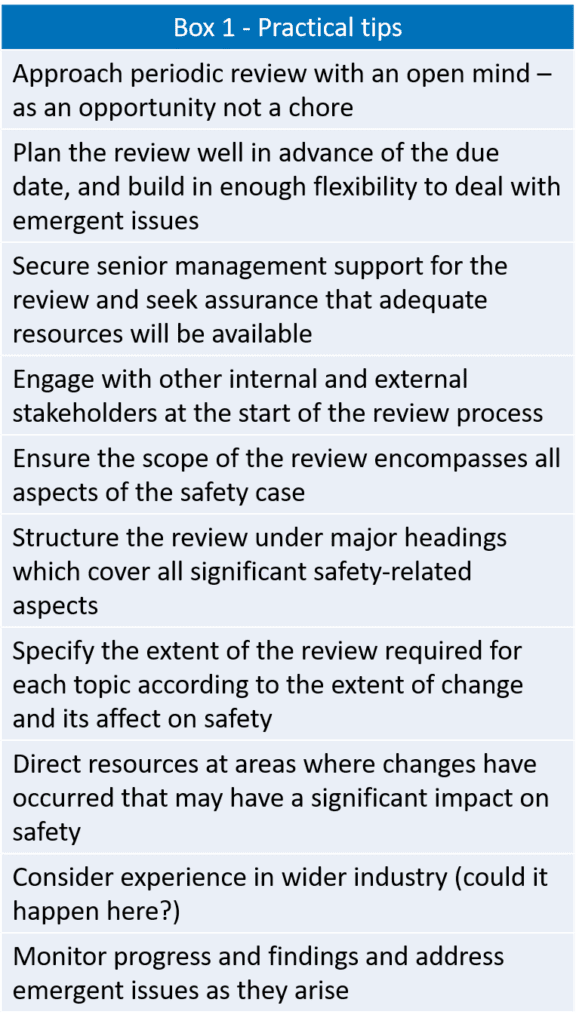

The key to success is to plan the review well in advance to ensure that adequate time is available for a systematic approach and to limit a more probing assessment to the major issues which may arise.

There are a number of practical tips that come from experience [see Box 1]. Of these, perhaps the most important is the early engagement of stakeholders to obtain buy-in and establish the full scope of the review before starting, together with the targeted use of resources for addressing significant changes.

STAKEHOLDER INVOLVEMENT

It may be tempting to conduct periodic reviews using a specialist safety team alone. However, to do so would be to pass up an excellent opportunity to engage with personnel across the organisation.

This is particularly true of operational personnel, whose detailed knowledge of the safety case may be limited, but who will have an excellent first-hand perspective of its practical implementation and direct experience of incidents.

Involvement of operators and maintainers can help confirm that the controls claimed in the written safety documentation are indeed operated and maintained accordingly. Moreover, this process can improve understanding on both sides, resulting in a safety case that better reflects operations and vice versa.

Involvement of regulatory personnel early in the process can often help to optimise the review. Insights and expectations can be identified and discussed and the review plan adjusted accordingly.

CONCLUSION

Periodic reviews are an important part of safely operating a major hazard facility. Approached positively they can present an excellent opportunity to take a fresh look at key aspects of the safety case using real experience and demonstrate to all stakeholders that the facility remains safe to operate for the foreseeable future.

This article first appeared in RISKworld Issue 16.