Simplifying Complexity – The challenges of fire and gas detection

Fire and gas detection enables the early detection of loss of containment incidents, which then demands automated or manual actions capable of significantly reducing the magnitude of consequences. For a long time, however, the performance of associated systems has been poor, with incident databases revealing that 36% of major and 69% of significant gas releases go undetected (Ref. 1). So what can be done to improve this situation?

© Shutterstock

THE PROBLEM

Ideally, a fire and gas detection system would detect all potential releases as soon as they occur. The reality, however, is that the diversity of release outcomes does not make this practicable. The range of influencing factors that affect hazard behaviour, such as release direction, wind speed, wind direction and ignition sources leads to a seemingly unlimited number of scenarios against which to design our detection system.

The problem is not limited to just choosing the most reliable equipment, we must also choose an appropriate layout. We could spend much effort procuring the most reliable equipment, but such efforts will be wasted if we do not support the design with an appropriate number and layout of detectors. Since the availability of the fire and gas system is dependent on both the equipment and the detector layout, traditional approaches to availability assessment, which do not consider the location (or coverage), are not sufficient for demonstrating fire and gas detection performance.

OTHER CHALLENGES

These issues are aggravated by the wealth of fire and gas detection equipment available on the market, each with their own supporting guidance, data sheets and manuals. Rather than helping, the range of options and information can serve to hinder the designer.

Not only do we have a large range of release scenarios to design against, we also have to consider detectors (and their varying capabilities) from competing vendors. All this comes together to form a potentially complex, multivariate design and analysis problem.

SIMPLIFYING COMPLEXITY

Like all other safety related systems, the requirements of the fire and gas detection system should be defined with an understanding of the hazards for each area of a facility. The hazards and associated risks then drive the specific performance requirements for the detection system (as well as the mitigative actions to be taken).

For fire and gas detection, it is actually helpful if we accept the assertion that not all potential release outcomes will be detected and instead, tailor our design solutions towards the most dominant risk contributors.

For example, in a highly congested volume the dominant hazard may be explosion (and subsequent escalation). In this case we need to provide a sufficient density of detectors to detect a flammable gas cloud before it could result in a damaging explosion. The detector layout for explosions will also likely be required to trigger automatic shutdown, placing further demand on our system to ensure there is a reliable signal for shutdown (e.g. by using a voting logic from multiple detectors).

For an open facility the main hazard may be migration of a gas to a public area, Here, perimeter monitoring achieved by line of sight detection may be more beneficial.

These two simple examples show us how understanding the risks and vulnerabilities of our facility provides valuable input to the fire and gas detection design philosophy, in particular the technology of choice and layout strategy.

GUIDANCE

When we consider the range of facility types (e.g. offshore and onshore), and hazardous outcomes (e.g. toxic dispersion, jet fire, explosion) the benefits of a publicly available and versatile standard methodology are clear.

To fill this void, the UK’s Energy Institute is in the process of producing guidance which provides a recommended approach to developing fire and gas detection philosophies. It is intended to be flexible, and equally relevant to small and large facilities, in both the onshore and offshore industries. The guidance promotes the requirement to assess hazards and risks by practicable means, utilising existing or planned studies (e.g. fire and explosion risk assessment and quantitative risk assessment) where possible. From this we can design our system against the dominant risks, and select an appropriate layout strategy and technology that can fulfil the performance requirements.

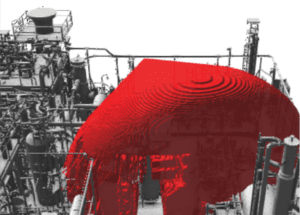

FIRE AND GAS MAPPING

So where does fire and gas mapping sit in all this? Fire and gas mapping has gained much traction in recent years, and provides a means to measure the coverage performance of our detector arrangement. It no doubt provides confidence and consistency (both within a facility and across industry) in proposed fire and gas detector layouts. The latest methods allow detailed assessment of thousands of release cases and automate the analysis of resultant data to ‘optimise’ our detector layout.

It is important, however, not to get too engrossed in mapping analysis and assume that with more analysis, comes greater risk reduction. No matter how sophisticated the approach to mapping, ultimately it should be treated as a verification exercise and applied only if appropriate for the detection strategy. For example, perimeter detection or dedicated spot detection are not ideal strategies for verification by fire and gas mapping.

Greater risk reduction benefits are likely to be realised if we apply equivalent effort in choosing the right technology and layout in the first place. For example, in some situations, it might be better to adopt acoustic detection technology, or consider infra-red gas cameras. These technologies are becoming more reliable and more cost effective; and we should understand the benefits these could bring to detection performance, rather than defaulting to the standard type of detectors and assuming that mapping will bring the optimum solution.

CONCLUSION

Designing a fire and gas detection system is a significant challenge – the range of scenarios, detector positions, technologies and minimal industry guidance leave the whole process ill-defined, leading to poor potential detection performance in practice.

First and foremost our design should be informed by risk assessment, from which we can define the specific detection requirements, choose appropriate technology and select the best layout strategy. Performing these activities initially will yield the greatest risk reduction benefits and only once these are completed are we in a position to decide whether mapping is needed. Crucially, this pragmatic approach will be reflected in the forthcoming Energy Institute guidance on fire and gas detection design.

References:

- RR1123, Fixed flammable gas detector systems on offshore installations: optimisation and assessment of effectiveness, HSE, 2017.